Intro: From RECCE Roots to DMR Ambitions

Like many of us, I didn’t start out with a high-end precision gas gun — I built with what I had, upgraded what made sense, and shot matches to get better. I recently stepped into the world of gas gun precision competitions and started out competing in the RECCE division, which limits shooters to 5.56/.223 and a maximum of 10x magnification.

My original rifle was built around a mix of parts I’d come to trust:

- Spikes Tactical lower — standard mil-spec I’ve owned for years

- BCM upper — known for tight, thermal-fit barrel seats

- Ballistic Advantage 16" HBAR barrel

- Geissele MK4 15" handguard

- Superlative Arms adjustable gas block

- A5 buffer system with Sprinco green spring and A5H1 buffer

- LaRue MBT-2S flat bow trigger

- Vortex Viper PST 2-10x with EBR-4 MRAD reticle in reptilia mount

- Dead air Sandman-S on Dead Air 3 prong Keymo Flash Hider

Nothing fancy — just solid parts, assembled with care.

This rifle served me well. I wasn’t winning trophies, but I held my own, placing 15th overall and 6th in RECCE division at my most recent match. More importantly, I could trust the gun to do what I asked of it. Consistent hits at distance, predictable recoil impulse, and no real quirks. I knew that if I missed a shot or dropped a stage, it was on me — not the gun. That level of confidence in your equipment goes a long way, especially in matches where small mistakes are magnified.

But I started watching how competitive the DMR division was getting. Bigger glass, more shooters in the division, more capable rigs. I decided it was time to step up.

The New Build: DMR Upgrade with Familiar Internals

With Geissele’s Blemula DDC receiver sets going on sale, I picked up a matched set, along with a DDC MK16 handguard. I transferred most of the components from my previous RECCE gun into this new build:

- Same Geissele bolt

- Same Ballistic Advantage barrel

- Same Superlative Arms gas block

- Same A5 buffer system

- Same LaRue trigger

- Same muzzle device and suppressor

The only real changes were:

- New Geissele receiver set and handguard

- New optic: Leupold Mk5HD 3.6-18x44 in an American Defense Recon mount

With the same core components and only a few changes, I expected equal or better performance — but that wasn’t the case.

What Came Next: Unexpected Accuracy Issues

I started noticing erratic accuracy, point-of-impact shifts, and inconsistent groups that didn’t match the performance I’d come to expect from the exact same barrel and bolt combo. Same ammo, same shooter, same environmental conditions — different results.

That kicked off a deeper dive into tolerance stacking, receiver fitment, and how small deviations between parts — even quality parts — can cause measurable problems in a precision gas gun.

In the next section, I’ll walk through:

- The specific issues I encountered (and how I ruled out variables)

- How tolerance stacking across receivers, barrels, and handguards can manifest

- What I did to diagnose the problem

- What worked — and what didn’t

Stay tuned for Part 2, where I dig into how I pinpointed the issue, what shooters can check when they run into similar problems, and whether this new DMR build is getting a redemption arc — or a teardown

Part 2: Assembly Realities, Accuracy Issues, and the Problem with Tolerance Stacking

Disassembly Tells a Story

When I broke down my original RECCE upper to start building the new DMR setup, something caught my attention immediately — the barrel slipped right out of the BCM upper. No heat. No persuasion. Just came out with minimal effort.

This wasn’t something I thought much of in the past, but it stuck in my head now. BCM uppers are known for tight barrel seats, often requiring a bit of thermal encouragement to install or remove barrels. That wasn’t the case here — and it was my first real clue that the Ballistic Advantage barrel extension might be on the smaller end of spec.

That theory held up when I later built a 6mm ARC in the same BCM upper using a Sons of Liberty Gun Works precision barrel. That one absolutely needed heat to seat — just as expected. So clearly, the barrel extension on the Ballistic Advantage barrel was undersized enough to slip fit into even a thermal-fit upper.

Building the Geissele DMR Upper

When I began assembling the new DMR rifle with the Geissele Blemula receiver set and MK16 handguard, I used the same Ballistic Advantage barrel. This time, I knew there wouldn’t be a thermal fit — Geissele uppers aren’t designed that way, and their tolerances are a bit looser by design to ensure compatibility.

Sure enough, the barrel dropped right in with zero resistance. Between a loose extension and a looser upper receiver bore, I was starting to suspect we had the perfect storm of tolerance stacking — but I hadn’t confirmed anything yet.

First Range Session — Something’s Off

I took the newly assembled rifle out for its first zero using Hornady 73gr ELD-Match. Temps were sitting around 100°F, so I chalked up the poor performance to the weather and called it a day. No group inside 2" at 100 yards, and far too inconsistent to try to adjust zero for.

I didn’t panic yet. Maybe I was off. Maybe it was mirage. Maybe the optic needed another look.

August 2nd — Reality Sets In

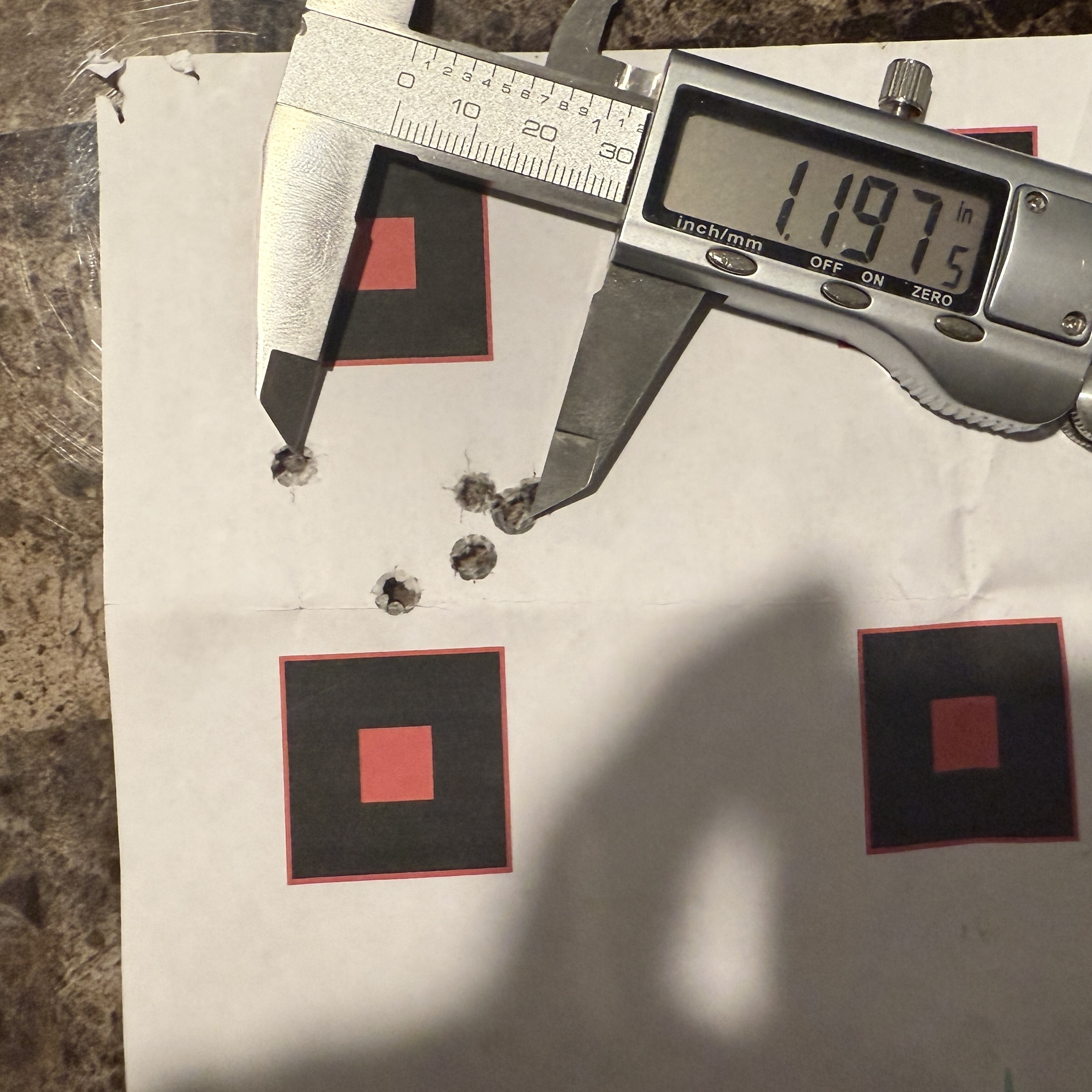

The day before a scheduled match, I hit the range again to rezero. Same ammo, same shooter, same results. Still couldn’t break the 2" group size. That’s when I started process-of-elimination testing.

I pulled the Leupold Mk5HD 3.6-18x off the Geissele build and mounted it to my 6mm ARC rifle — where it promptly shot a sub-1.5” group (well acceptable for a handload i haven’t fully optimized). This eliminated the shooter, optic, and mount from the equation.

It’s worth noting the scope was mounted using Fix It Sticks, torqued to spec, and rechecked. Everything on paper was right — but the target said otherwise.

To further rule out common issues:

- The barrel only had ~500 rounds through it — far from shot out

- I was using Hornady 73gr ELD-M from the same lot that previously performed well

- The rifle was consistently supported on a bipod and rear bag, with no variation in pressure or posture

- The 20-round string showed no POI shift, just a completely inconsistent, 2–3" scatter group

This wasn’t shooter error or equipment torque — this was something deeper. And with no time left to switch divisions or prep match ammo for the ARC, I made the call: run the Geissele gun as-is and see what I could learn

Match Day: August 3rd – Humbling, but Educational

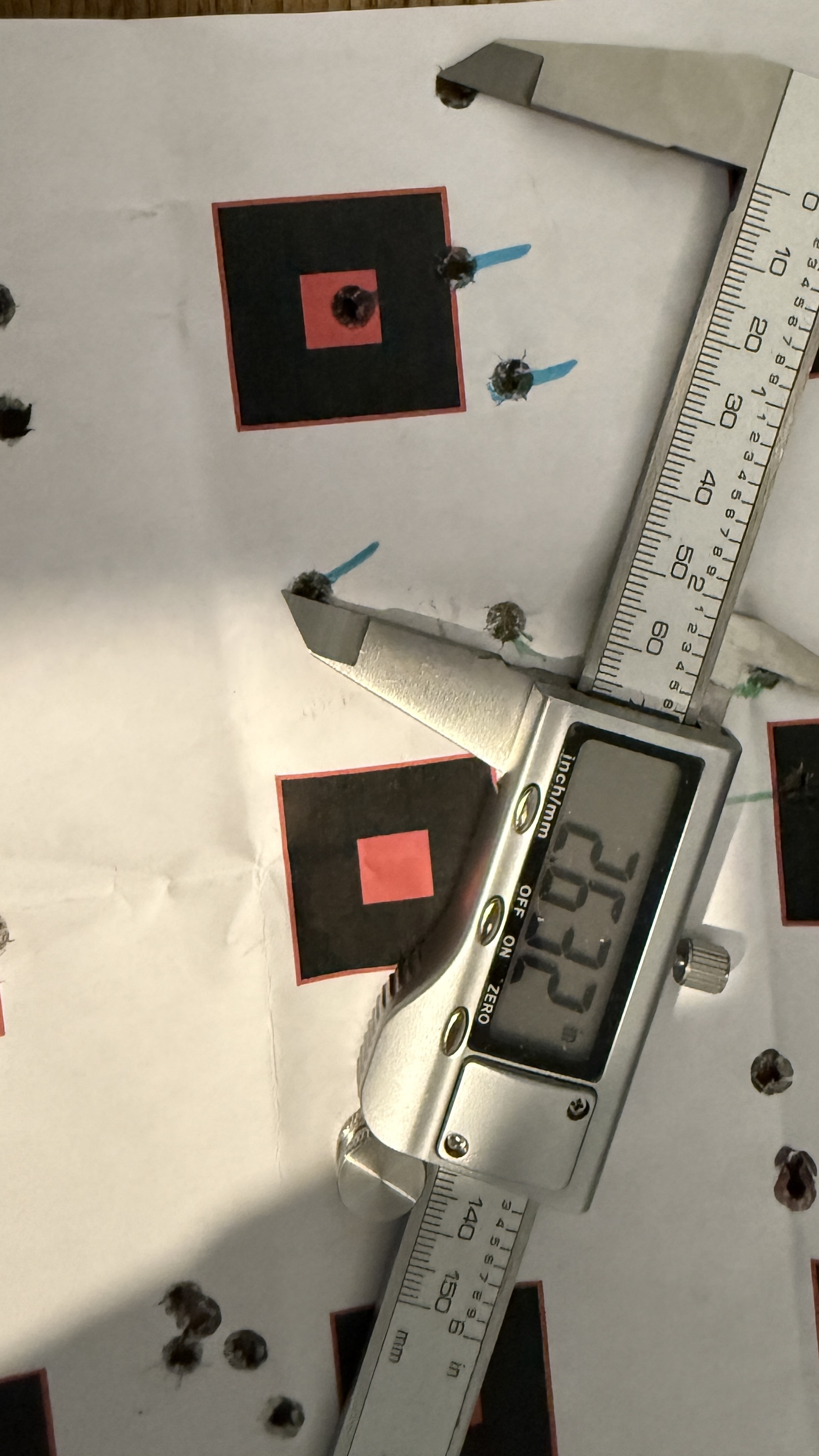

I hit the zero range early that morning to verify before the match. The group was, again, a scatterplot — twenty rounds dancing around the outer edge of a 2" circle. No consistent center, no tight grouping, and nothing confidence-inspiring.

The match that followed was brutal. Where previous gas gun matches I’ve shot leaned toward larger targets — full-size IPSCs, reduced silhouettes — this one skewed PRS-style, with lots of 1–2 MOA targets ranging from 300 to 650 yards. Normally, that’s tough but achievable with a well-built precision gas gun. You’ve got to do your part, but the rifle should hold its own. Unfortunately, mine couldn’t even hold a 2 MOA group at 100 yards, which made for a very long day.

I ended the day with a ~12% hit rate, struggling stage after stage. I wasn't surprised — I simply couldn't trust the rifle to consistently land shots. But I wasn’t there to win, and I wasn’t there to make excuses. I was there to learn — and this rifle was teaching me something.

The Diagnosis: Tolerance Stacking

I recalled a podcast conversation recently where barrel lapping and bedding were mentioned as solutions for improving AR accuracy. I’d never needed to go down that route — my previous BCM builds were tight enough to avoid it.

But this time, I had clear symptoms:

- Known barrel on the looser side of spec

- Upper receiver not intended to be thermal fit

- Accuracy that degraded significantly despite known-good components

I reached out to a respected gunsmith and builder who offers AR barrel lapping and bedding. After hearing my story, he agreed to take the rifle in — and asked me to document before-and-after accuracy results.

He told me it’s rare that someone brings in a rifle with this much pre-diagnosis, match-grade ammo, and performance benchmarks already gathered. I wasn’t just sending him a “bad shooter” complaint — I had data.

To explain the issue plainly:

Tolerance stacking is when multiple parts, each within spec, end up combining in a way that creates a measurable performance issue.

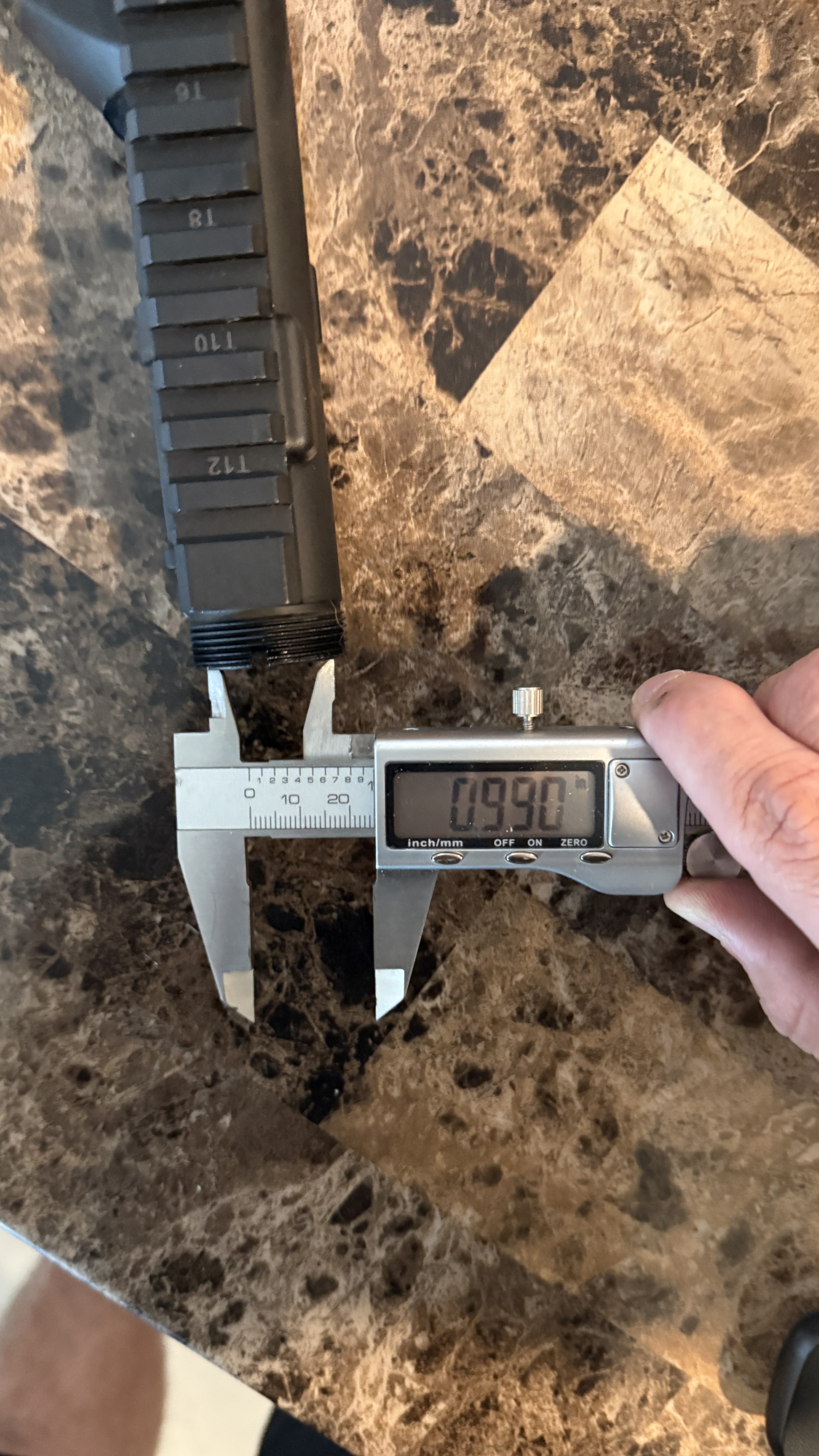

Imagine Part A (your barrel extension) is spec’d at 1.000" with a ±0.010" tolerance. It comes in at the minimum of 0.990".

Now Part B (your upper receiver bore) is also in spec at 1.005", with the same ±0.010". It happens to be at the maximum: 1.015".

That leaves a 0.025" total clearance, which is just enough room to allow for barrel movement under recoil, inconsistent harmonics, or poor repeatability from shot to shot.

That’s likely what I ran into — and the fix is to remove that tolerance gap through a process of lapping and bedding the barrel into the upper.

This is no knock on Geissele, Ballistic Advantage, or any manufacturer involved. Every machining process has a tolerance range, and all of these parts are likely within spec. But when parts from different sources happen to fall on opposite ends of that range, you get tolerance stacking — and that can lead to problems, especially in precision applications. It's just something you need to be aware of and account for when chasing tight groups from a gas gun.

What’s Next

I haven’t sent the upper off for bedding just yet. In the next part of this series, I’ll go over the actual measurements I took during disassembly to document the fit between the barrel extension and the upper receiver. This data should give us some hard numbers to confirm whether or not tolerance stacking is truly at play — and just how much excess play there really is between the parts.

This next part will close the loop:

- Does bedding solve the accuracy issues?

- How does it affect group size, POI shift, and consistency?

- Is this a one-off problem, or a real-world case study in tolerance stacking?

Stay tuned — this build isn’t done teaching me (or maybe you) just yet

08/06/2025 Part 3: Measuring Component Fit – Upper Receiver Bore vs. Barrel Extension

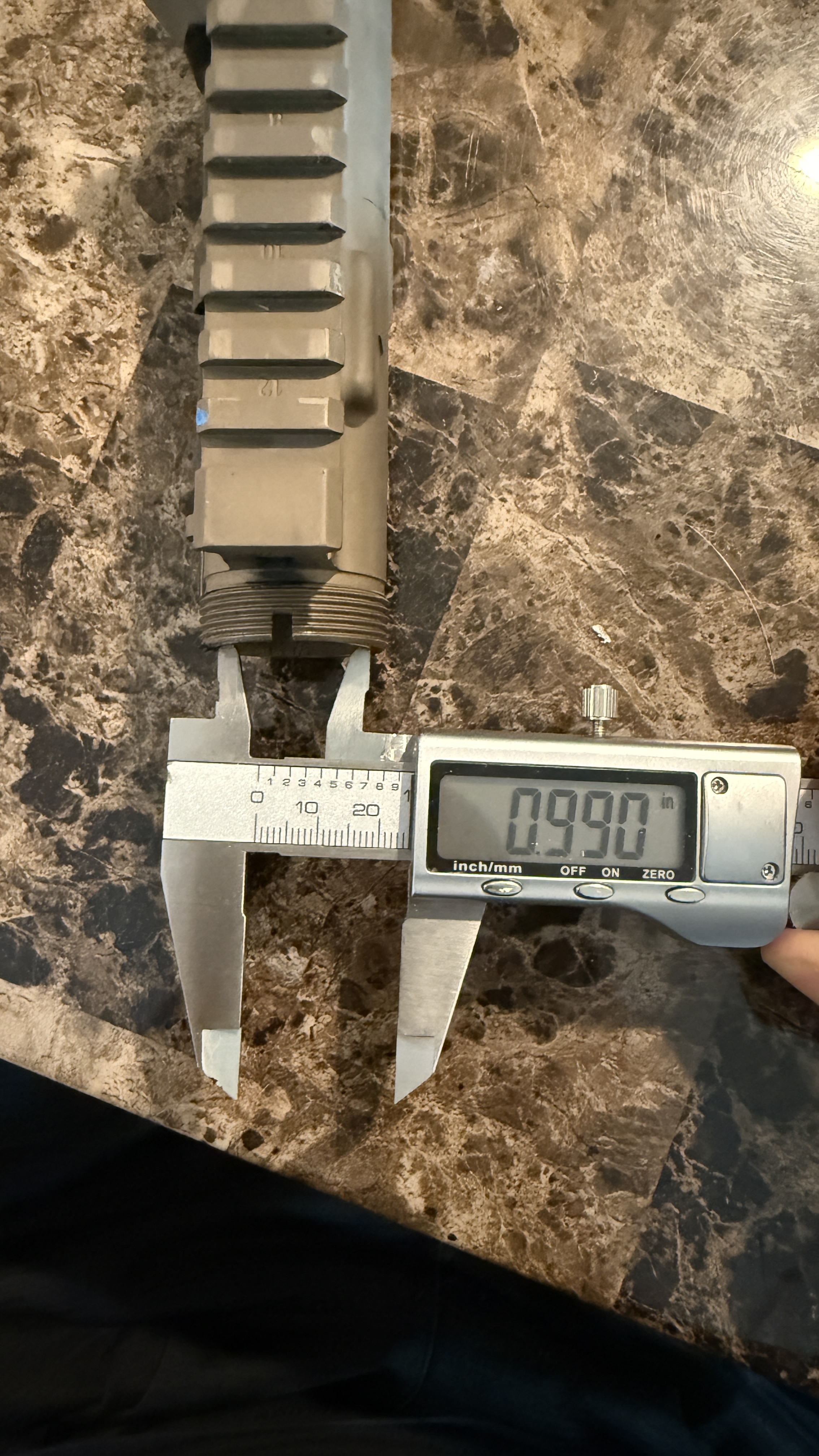

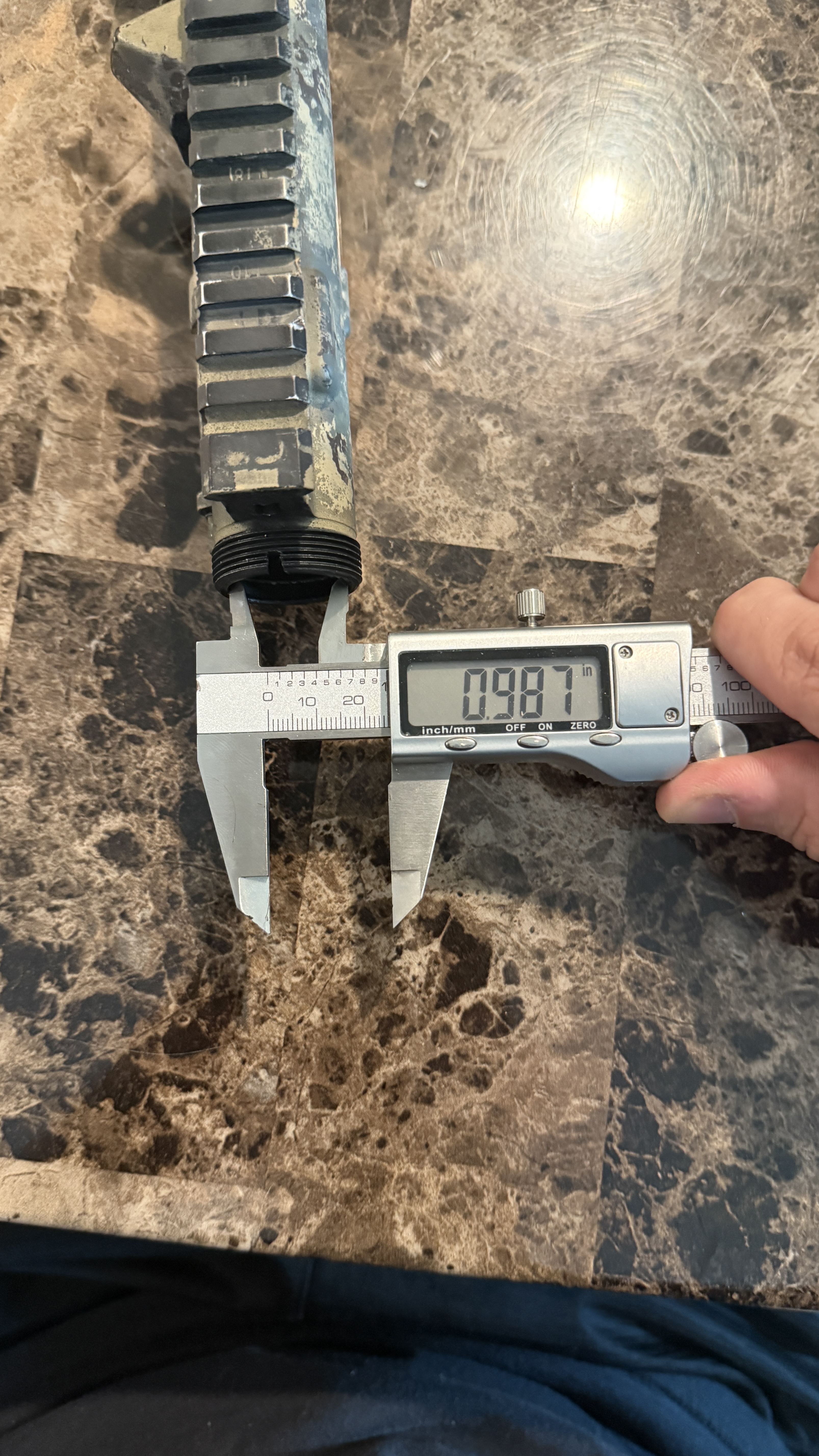

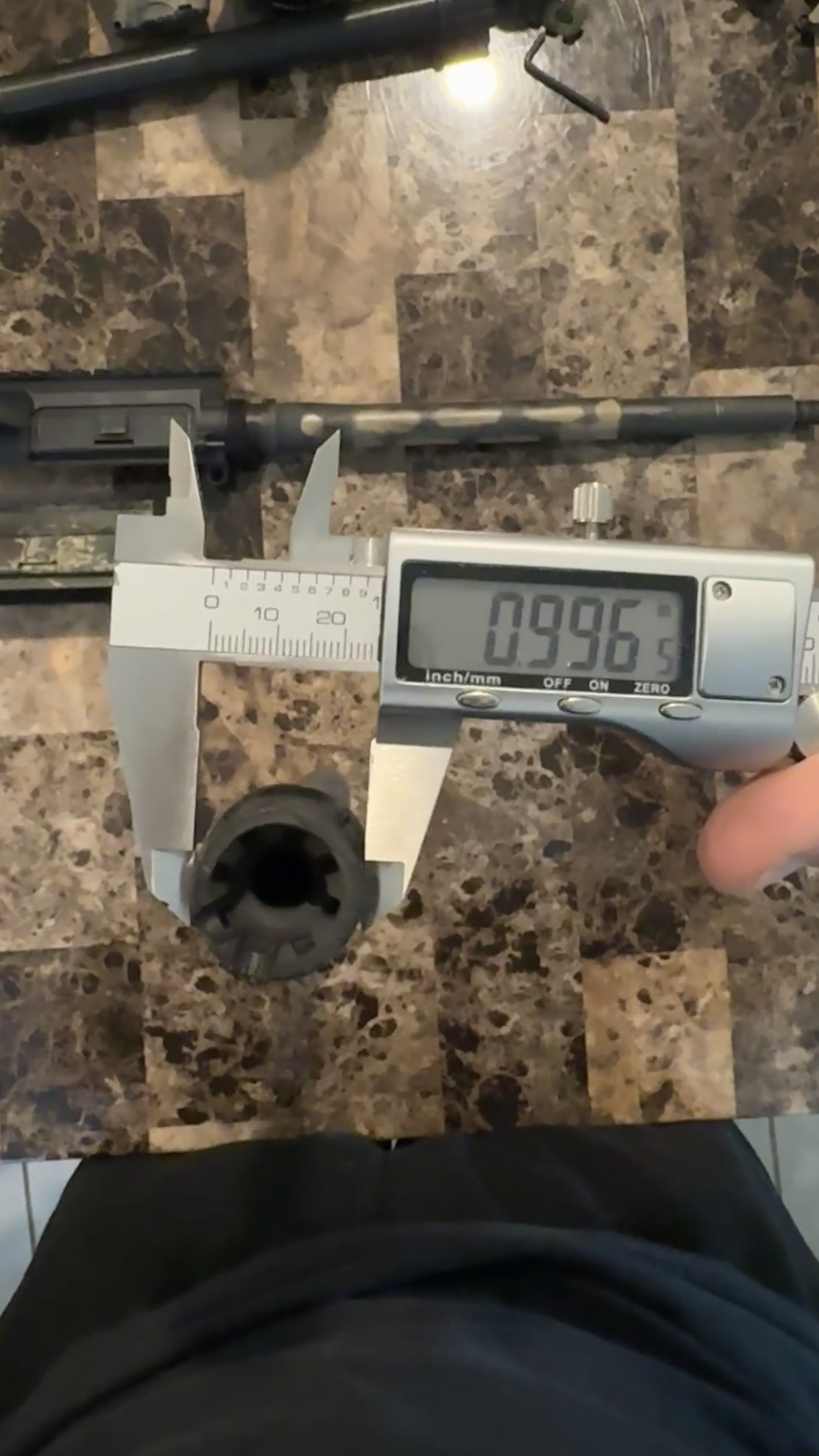

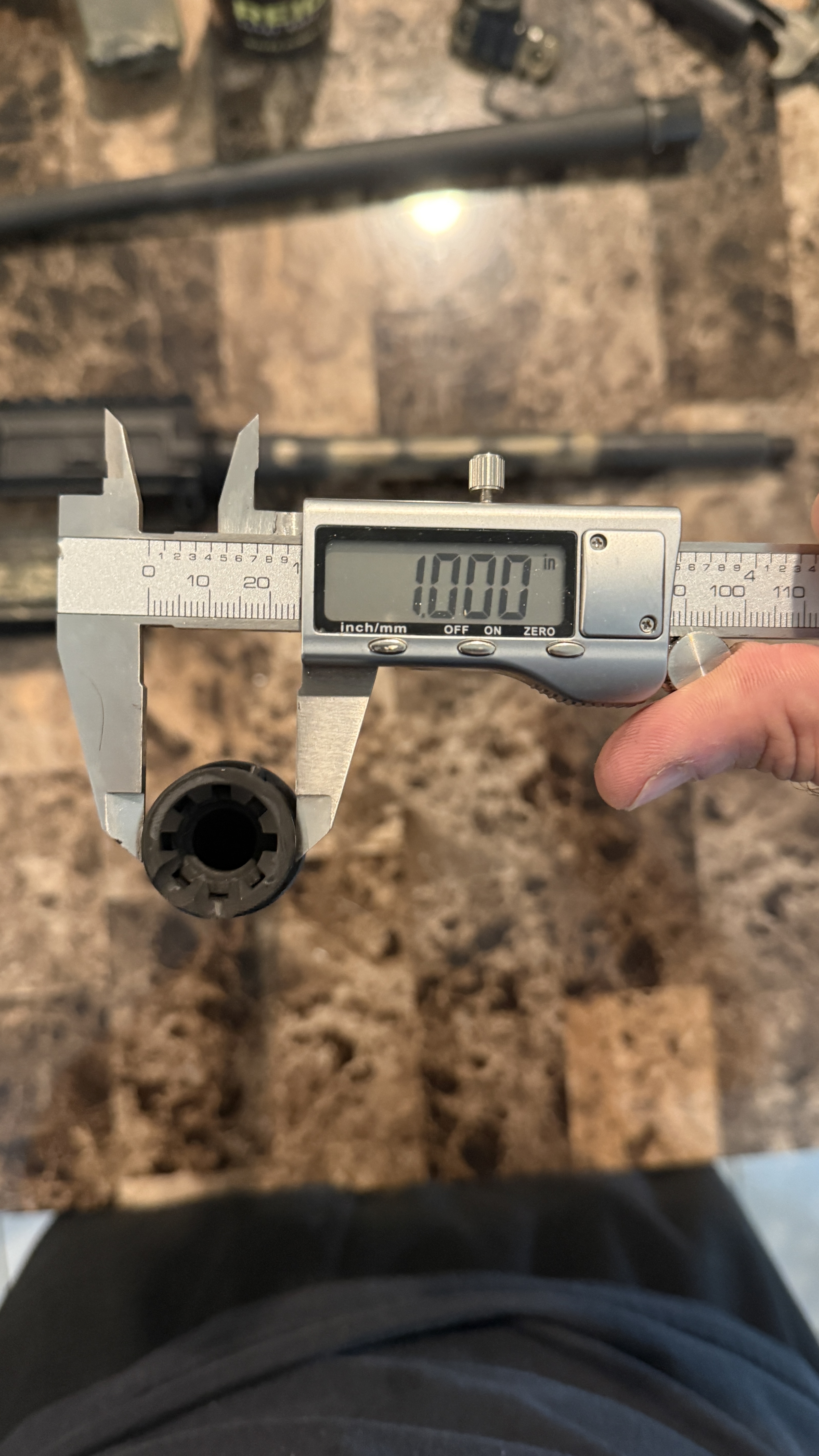

To explore how part-to-part variance in AR-pattern rifles might contribute to mechanical inaccuracy, I disassembled three complete uppers and took measurements of the upper receiver internal bore diameter and barrel extension outer diameter using a digital caliper. While this tool provides basic dimensional reference, it is not ideal for accurately measuring internal diameters. The inside measuring jaws may read consistently under true ID, which likely explains why all three upper receivers appeared to measure smaller than the corresponding barrel extensions.

As a result, while the upper receiver bore measurements are useful for comparison relative to each other, they should not be used to calculate exact clearance between a barrel and its mating upper. The values below are best interpreted in terms of relative fit rather than absolute clearance.

Measured Setups:

|

Upper Receiver |

Bore ID (in.) |

Barrel |

Extension OD (in.) |

Observed Fit |

Notes |

|

Geissele |

0.990" |

Ballistic Advantage |

0.9965" |

Slip fit |

Consistent but loose fit |

|

BCM |

0.987" |

SOLGW 6mm ARC |

1.000" |

Interference fit |

Required thermal fitting |

|

Aero Precision |

0.990" |

Expo Arms 11.5" SOCOM |

0.996" |

Slip fit |

Consistent but loose fit |

Geissele, BCM and Aero upper internal bores compared

Barrel extensions compared Ballistic Advantage, SOLGW Precision SPR, Expo Arms

Key Observations:

- BCM Upper + SOLGW Barrel: The tightest interface of the test group. The combination displayed a true interference fit and required thermal fitting to seat or remove. Once installed, there was zero rotational or axial play.

- Geissele + Ballistic Advantage: Exhibited a slip fit that allowed for easy installation and removal. While the bore measured smaller than the barrel extension, this is likely due to caliper inaccuracy — the important observation is that there was no resistance during install, implying a looser fit.

- Aero + Expo Arms: Similar in fit to the Geissele + BA combo, with minimal insertion resistance and no heat required.

Takeaways:

- Due to limitations of caliper-based internal measurements, bore ID readings cannot be used to determine exact fitment clearance. However, they can reveal consistent trends between uppers, such as the BCM's tighter bore compared to Geissele and Aero.

- The SOLGW barrel appears to be intentionally oversized, supporting its branding as a precision product and aligning with fitment strategies intended to reduce mechanical slop.

- The Geissele upper has one of the largest bores, and it would be worth measuring a Geissele barrel extension in the future to evaluate if their design philosophy involves matched oversized parts for optimized pairing.

- Even seemingly minor fitment differences — such as those seen when installing the same barrel in two different uppers — can introduce mechanical variance that may impact point-of-impact consistency or group dispersion.

Shim Implementation for Controlled Testing

Rather than moving the Ballistic Advantage barrel to another upper, I elected to shim the BA barrel in the Geissele upper to create a before-and-after comparison under otherwise identical conditions.

- Shim thickness: 0.001"

- Shim width: ~1" as packaged; trimmed around feed ramp area to prevent interference

- Installation: Heat required to seat the barrel; once cooled, the barrel could not be removed without heat or excessive force

- Current phase: Testing shim-only fitment; bedding compound will be introduced in a later phase to compare shim vs. shim + bedding

For an additional data point, I installed the SOLGW 6mm ARC barrel into the Aero upper with a 0.001" shim, also achieving a thermal interference fit in what was originally a slip-fit upper. This will allow comparison between:

- SOLGW barrel in a true interference-fit BCM upper

- SOLGW barrel in a slip-fit Aero upper converted to interference fit via shimming

Firing Protocol:

|

Parameter |

Specification |

|

Distance |

100 yards |

|

Rest/Support |

Front & rear bag |

|

Rounds per Group |

5-shot groups, part of 20-round strings |

|

Groups per Config |

Minimum 4 targets (20 rounds total) |

|

Rate of Fire |

Moderate pace; simulate match tempo |

|

Suppressor |

Optional; consistent per config |

|

Ammo Type |

Same lot/make across all tests |

|

Zero Adjustment |

Zero each upper once, then leave fixed |

For the Ballistic Advantage barrel, I will use Hornady Match .223 73gr ELD-M as the primary load due to its past consistency. I may also test AAC 77gr OTM - as i have some on hand though it has shown excessive velocity ES and SD numbers and Federal Gold Medal 77gr or another match grade load depending on what I can get my hands on.- For the SOLGW 6mm ARC barrel, test loads will include Hornady Black 105gr, Hornady Match 108gr, and Hornady V-Match 80gr.

- Each test will consist of a 20-round string, broken into four 5-round groups per target, measured both individually and collectively.

- Special attention will be paid to POI shift during the string to capture effects of heat and realistic stage simulation. A cooldown will follow each full string.

- This method reflects the typical match stage structure: 15–20 rounds in ~110 seconds, providing more meaningful real-world accuracy data than isolated 3–5 shot groups with full cooldowns.

Measured Data per Group:

|

Metric |

Description |

|

Group Size (MOA/inches) |

Measured center-to-center |

|

POI Shift |

Cold bore vs. hot bore |

|

Group Consistency |

Spread of group sizes across 4 targets |

|

Visual Observations |

Stringing, fliers, symmetry |

|

Mechanical Notes |

Torque values, seating consistency |

This approach isolates the impact of barrel-to-receiver fit by comparing:

- Baseline slip fit

- Shim-induced thermal interference fit

- Interference fit via original machining (BCM)

Closure: Purpose of Shimming

The goal in shimming is to reduce or eliminate axial play between the barrel extension and the upper receiver bore. By achieving a thermal interference fit, the interface becomes more rigid, which can:

- Reduce micro-movement under firing stress

- Increase overall mechanical accuracy

- Minimize point-of-impact shift during extended strings of fire, where heat expansion in the upper could otherwise loosen the fit and alter alignment

This method provides a controllable way to tighten tolerances without permanently altering the receiver, and it creates a repeatable test bed for evaluating the effect of fitment on accuracy in gas gun platforms.

In the next phase—likely following the next match—I will experiment with adding Loctite 620 (a sleeve retaining compound) in conjunction with shims to fill any remaining microscopic gaps. The goal will be to achieve a rock-solid, accurized AR-15 upper receiver and prove (or disprove) the idea that gas guns can truly perform as precision rifles.

Part 4 — October 18 Range Session and the Turning Point

After the October 18 range session, it was obvious the Ballistic Advantage 5.56 barrel was still not behaving—even after creating a tight, thermal-fit shimmed interface in the Geissele upper. Accuracy remained unpredictable, and the rifle never settled into a repeatable pattern. At that point, I pulled the BA barrel and installed a proven performer: my Sons of Liberty Gun Works 13.9" 6mm ARC precision barrel.

The goal was simple:

See whether the Geissele receiver performed differently when paired with a different, known-good barrel.

A Simple Install — and the Results Spoke for Themselves

For this test, I did no accurizing whatsoever.

No shims.

No bedding.

No tricks.

Just a straightforward install and proper torque—exactly how the vast majority of shooters would assemble an upper.

The results were immediate and impressive. The rifle printed sub-MOA groups with ease, produced smooth and consistent recoil, and showed absolutely predictable point of impact. It was the first time during this whole process that the rifle actually behaved like a match gun.

Encouraged, I ran this exact configuration at The Gas Gun Show on November 2nd, and the rifle shot phenomenally all day long. Stages felt controlled, transitions were natural, and the ARC cartridge again proved why it’s becoming a favorite in gas-gun competition.

One Limitation: Handguard Space

My only complaint with the 13.9" ARC build was handguard length.

With:

- a bipod mounted forward,

- the natural curve of ARC magazines, and

- certain stage props requiring bag-based support,

the short handguard made shelfing the rifle on a Schmedium Game Changer a bit tricky. On specific barricades, I simply didn’t have the real estate or leverage a longer gun provides.

If not for this factor, that 13.9" SOLGW ARC setup would stay as both my match rifle and my hunting rifle. It’s that good. But stability is king in some stages, and stability favors length.

Because of this, the 13.9" SOLGW barrel is now going back into the BCM upper, where it originally lived—and where it fits the role of a compact precision/hunting rig perfectly.

The BA Barrel: On Pause

While the Ballistic Advantage barrel experiment has been immensely educational, it’s shelved for now. I need a dependable match rifle, not last-minute troubleshooting marathons the week before competition. The BA barrel will get more testing, but not until after I establish a stable, repeatable match-ready platform.

Next Phase: Shaw Barrels .22 ARC — Moving Into Open Division

With the SOLGW test proving the Geissele upper is perfectly capable when paired with the right barrel, it’s time to give that receiver a new mission. The Geissele upper will next wear a Shaw Barrels .22 ARC 18" HBAR, paired with the original 15" Geissele MK16 handguard.

Shaw’s .22 ARC barrels have been getting strong reports, and the cartridge itself is rapidly gaining traction. Running .22 ARC will push me into Open Division in future Gas Gun Show matches—a division that grows every match as ARC-based setups become the standard for serious competitors.

Looking Forward

Here’s the current roadmap:

- BCM Upper + SOLGW 13.9" 6mm ARC

→ Becoming my dedicated compact match/hunting hybrid. - Geissele Upper + Shaw 18" .22 ARC + 15" MK16

→ Becoming the new primary match rifle in Open Division. - BA 5.56 Barrel

→ Staying benched until I can continue deeper accuracy testing with bedding and concentricity checks.

This project began as a tolerance-stacking mystery and has evolved into a full exploration of what truly matters in precision gas-gun performance. With the .22 ARC build underway, the next chapter promises even more data—and maybe a new top performer.

Soon I will be composing a separate in depth T&E Brief on the Shaw barrel.